Copyright © 2009-2020

North Manchester

Historical Society

All rights reserved.

Please contact

our Center for History

if you find

inaccuracies or

inappropriate content.

|

Source: North Manchester Journal, October 7, 1909

CLOSING FOUNDRY CONTRACT.

Mr. Garwood Here With Force of Men to Go to Work

at Once.

A.R. Garwood and two or three of his associates from

Wellsburg, West Virginia, are here this week, and the

contracts were being closed Wednesday by which the

Industrial association and the citizens of North

Manchester will contribute two thousand dollars toward

assisting to start a foundry. The old Dunbar building

has been bought for this purpose, and a force of men

will be put to work in a few days making the needed

changes, so that it is expected the foundry will be

ready to run by the first of January. Not quite all of

the two thousand dollars necessary for the fund has been

subscribed, and the Industrial association has to draw

on its treasury to supply the balance.

Monday evening there was a meeting with Mr. Garwood that

resulted in considerable enthusiasm, and at which the

soliciting committees reported. Still farther canvass

was made Tuesday with good results. A foundry is an

enterprise for which there is great demand here, as has

been mentioned before in the Journal and it is to be

hoped that the conference that was being held Wednesday

when the Journal went to press will result in an

agreement that will quickly produce the results, and

about which there will need to be no delay.

Source: Aurora (1927) Ad:

North

Manchester Foundry Co. Inc.

The foundry is one of

the leading industrial enterprises of the city. It is

chiefly occupied in making school desk and opera chair

castings for the Peabody School Furniture Company.

Practical and economical heating and laundry stoves are

also products of the foundry.

Manchester College has been more closely connected with

the foundry than perhaps any other business firm in

North Manchester. Mr. John Stauffer, for many years the

president of the corporation, was at the time of his

death one of the trustees of the college; Robert

Stauffer, our basketball coach is Secretary-Treasurer;

and Prof. Roy Dilling, a member of our Music faculty is

Vice President. They have been friends and supporters to

whom we are greatly indebted.

Source: Ravelings

(1949) Ad:

North Manchester

Foundry

Makers of HEATING AND LAUNDRY STOVES

Also Grey Iron Castings

Phone 153

Source: News-Journal, August 16, 1973, Centennial

Section

Foundry Incorporated 1911

The North Manchester Foundry

Company was incorporated July 3, 1911. Common stock was

issued to J.C.F. Martin, president; W.J. Ranger,

vice-president and John Stauffer, secretary-treasurer.

John Stauffer purchased the stock of W.J. Ranger in 1913

and the stock of J.C.F. Martin in 1919. Stauffer had

come to North Manchester earlier after a foundry he had

operated in Dayton, Ohio burned out.

The major part of the common stock

remained in the Stauffer family until January 1947, when

all of the outstanding common stock was purchased by the

M.H. Detrick Company with main offices in Chicago. After

this transaction the foundry became a division of the

M.H. Detrick Company.

John Stauffer served as general manager from 1911 until

his death in April of 1927. His son, R.M. Stauffer

succeeded him as general manager and operated the

foundry until 1947 at which time he was responsible for

the sale of the foundry to the M.H. Detrick Company.

Due to the successful operation of the foundry from 1927

to 1947 the M.H. Detrick Company appointed R. M.

Stauffer a vice president and retained his services as

general manager until his retirement in 1968. Upon

retirement R.M. Stauffer was replaced by Rolf Westman

who is currently operating the foundry as vice president

and general manager.

The foundry was originally organized to manufacture

castings for the Peabody Seating Company. for twenty

years this casting production represented about 90

percent or more of the total production. In the early

1930s the foundry was forced to branch out into other

lines of castings due mainly to the fact that steel

moveable school desks began to replace the cast iron

stationary desks.

Among other types of production, the foundry began the

manufacture of coal and wood burning heating and

laundry stoves. The company produced 20 to 25 thousand

stoves a year in the late 1930s and early 1940s. The

decline of coal for home heating soon reduced the need

for stove production.

In 1935 the foundry began making castings for the Ford

Meter Box Company in Wabash. This business has been

continued since that time and the Ford Meter Box Company

is still considered among the larger customers for

castings from the foundry.

During World War II the foundry produced farm machinery

castings for the J.I. Case Company of Rockford, Ill.

These castings carried a high priority rating,

therefore, the foundry experienced no difficulty in

obtaining raw materials for their war time production.

Soon after World War II the M.H. Detrick Company bought

the foundry. At that time Detrick operated two other

foundries, one at Newark, N.J. and the other at Peoria,

Ill.

The M.H. Detrick Company closed the Newark foundry

operation in 1958 and moved the production pattern

equipment to the North Manchester plant. Expansion of

the North Manchester facility was planned and

construction started in November 1959 with a rebuilding

and addition to the plant.

In 1964 the Peoria, Ill., foundry was closed and more

equipment moved to North Manchester. At the present time

the North Manchester Foundry is the only M.H. Detrick

foundry in operation.

Since construction program started in November 1959, it

has been a continual expansion and improvement with

future plans still being made. In 1965 a pallet line

molding operation was installed with conveying equipment

and lift trucks for a much improved materials handling

operation.

In 1968 an air conditioned lunch room was provided for

employee convenience and comfort. In 1970 a first aid

room was installed along with more production

improvements.

With air pollution control laws being enacted plans were

formulated and two new electric induction furnaces were

installed and began operation in October of 1971. The

electric furnaces replaced the cupola melting operation

that had been used in the foundry for 60 years. The

electric melting operation has been successful enough to

warrant a decision by the M.H. Detrick Company to add a

third electric furnace for additional expansion to the

production facility. Plans call for the third furnace to

be in operation by the end of 1973.

The 200 employees of the North Manchester Foundry

participate in the following employee benefits:

1. Savings and Profit Sharing.

2. Group hospitalization and life insurance.

3. Vacation pay.

4. 10 paid holidays.

5. Other company sponsored activities including

participating and spectator sports.

6. Profit sharing cash bonus.

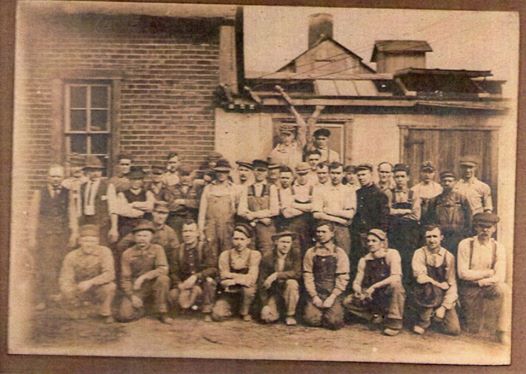

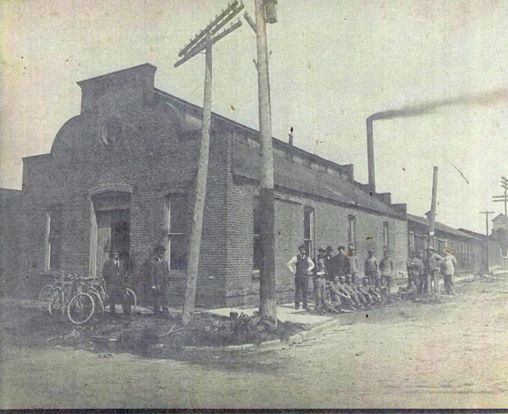

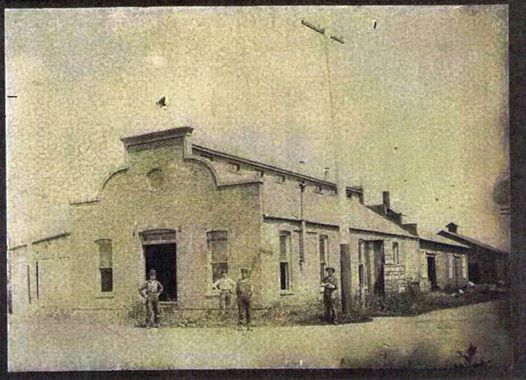

VINTAGE PHOTOS OF NORTH

MANCHESTER FOUNDRY & WORKERS-

Source: NMHS Newsletter Nov 2002

North

Manchester Foundry

The North Manchester Foundry

Company was incorporated July 3, 1911. Common

stock was issued to J. C. F. Martin, president

W. J. Ranger, vice-president and John Stauffer,

secretary-treasurer. John Stauffer purchased the

stock of W. J. Ranger in 1913 and the stock of

J.C.F Martin in 1919. Mr. Stauffer had come to

North Manchester

|

| |

| |

Page One

|

|

| |

|

|

|

earlier after a foundry he

had operated in Dayton, Ohio burned out. The

major part of the common stock remained in the

Stauffer family until January 1947 when all of

the outstanding common stock was purchased by

the M. H. Detrick Company with main offices in

Chicago. After this transaction the foundry

became a division of the M. H. Detrick Company.

John Stauffer served as

general manager from 1911 until his death in

April, 1927. His son Robert M. Stauffer

succeeded him as general manager, and became a

vice-president of the Detrick Company and

continued to manage the North Manchester plant.

The foundry is one industry that has never called

upon the town for financial assistance.

The foundry was originally

organized to make castings for the Peabody

Seating Company and for approximately twenty

years this production was 90 per cent or more of

the total castings produced. In the early 1930's

the foundry was forced to branch out into other

lines of castings due mainly to the fact that

steel movable school desks began to replace the

cast iron stationary desks. Among other types of

production, the foundry began the manufacture of

coal burning heating and laundry stoves,

producing 20 to 25 thousand stoves a year in the

late 1930's and early 1940's. Then the use of

coal began to decline and stove production was

phased out. In 1935 the foundry began making

castings for the Ford Meter Box Company at

Wabash.

During World War II the

foundry produced farm machinery castings for the

J. I. Case Company of Rockford, Illinois. As

their castings carried a high priority rating,

the foundry experienced no trouble in getting

raw materials. Soon after the war when the M. H. Detrick Company purchased the plant the work for

the company took an increasing percentage of the

total capacity. This production was engineered

refractory heat enclosures which are applied to

open hearth

|

|

| |

|

| |

|

|

Page Two

|

|

|

|

|

furnaces, metallurgical and

steel processing furnaces, refuse incinerators,

clinker coolers for the cement industry, etc. M.

H. Detrick Company operated foundries at North

Manchester and Peoria, Illinois to produce

mechanite metal for heat resisting castings

which support the special fire brick shapes.

Foundry operations were not

highly mechanized due to the great variety of

patterns involved in their production. The new

building improved production somewhat going from

melting 22 to 24 tons of iron daily to a

capacity of 30 to 36 tons daily.

In 1959 the plant began a

rather unique plan of construction of a new

building. The entirely new structure was built

over the old structure without interrupting

operations within the old structure. Once the

outer structure was complete, the removal of the

old structure began and that was completed by

1961. In the summer of 1961, on the fiftieth

anniversary of incorporation the management

considered having a day for open house but

decided it was impractical. They did invite any

who were interested in watching the iron being

poured to call and arrange to watch any

afternoon from Monday to Friday. Visitors on any

day were to be limited. The new building had a

50 per cent greater capacity than the old.

Smoke pouring from the

chimney of the new plant was a daily sight as

the fire was lighted in the big cupola every

morning about 10:00 o'clock. Within a few

minutes after the proper heat was reached the

smoke was dissipated and the cupola was loaded

with the metal to be melted. Iron was poured

every day from 2:00 o'clock until 4:30.

In addition to Robert

Stauffer, other members of the management staff

in 1961 were Clyde Brindel who had been with the

foundry since 1915 and became plant

superintendent in 1935; Don Roberts who joined

the company in 1927 and had been foundry

superintendent since 1945; Jack Richards who had

worked since l938 and had been assistant foundry

superintendent since 1959; Dale Berry who had

worked since 1947 and had been in charge of

quality control since 1960; Gene Coe had been

office manager since 1955. Workers in the plant

included Dick Reed, Laymon Howard, Ronnie

Bridegroom, Roy Hippensteel , Homer Kerr and

Charlie Conrad. There were as many as 85 on the

payroll in about 1960.

|

|

[Continued on Page Four]

Page Three

|

|

|

|

|

The North Manchester Foundry

was among the first in this area to install a

profit-sharing plan for its employees beginning

in 1935. Group insurance benefits began in 1929,

vacation pay in 1944, holiday pay in 1950 and an

employee loan plan since 1954. All of these were

innovative at the time.

|

|

|